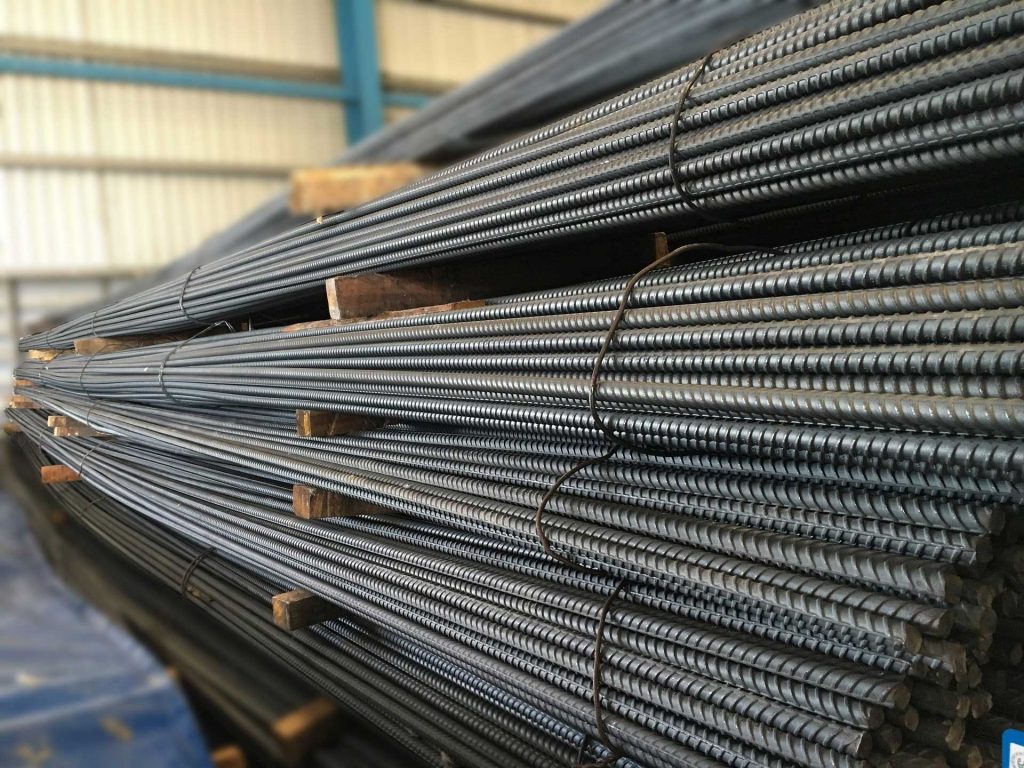

TMT (Thermo-Mechanically Treated) bars are steel bars used in the construction industry. They are made by a process that involves heating the bars to a high temperature and then cooling them rapidly. This process improves the strength and ductility of the steel, making it more resistant to bending and breaking. TMT bars are commonly used in the construction of buildings, bridges, and other structures. They are also used in the reinforcement of concrete.

TMT bars are made from high-grade steel and are known for their strength, durability, and resistance to corrosion. The process of TMT involves heating the steel bars to a temperature of around 800-900 degrees Celsius, followed by quenching in water or oil. This process is called the quenching and self-tempering (QST) process.

Visit this Page for More Information: Start a Business in Steel Industry

The heating and cooling process changes the microstructure of the steel, making it stronger and more ductile. The TMT process also imparts a distinctive pattern, known as the Fe-O-Fe (ferrite-pearlite-ferrite) pattern, on the surface of the bars. This pattern is an indication of the quality of the TMT bars and is used as a benchmark for quality control.

TMT bars are available in different grades, such as Fe 415, Fe 500, Fe 550, and Fe 600, depending on the strength and ductility required for a particular application. They are also available in different sizes, from 6mm to 32mm in diameter.

TMT bars are widely used in the construction of buildings, bridges, flyovers, and other structures. They are also used in the reinforcement of concrete, where they are used to provide strength and support to the concrete structure. TMT bars are also used in the construction of foundations, beams, columns, and slabs.

Related Business Plan: TMT Bars

Overall, TMT bars are an essential component in the construction industry providing strength, durability, and resistance to corrosion. They have replaced traditional mild steel bars and are widely preferred due to their superior properties.

Market Size in India:

TMT bars are a widely used steel product in the construction industry in India. According to a report by Research and Markets, the market size of TMT bars in India was valued at around INR 253.5 billion (approximately $3.5 billion) in 2020. The demand for TMT bars is mainly driven by the growing construction industry, which is expected to continue growing in the future.

The Indian construction industry is one of the largest in the world and is expected to grow at a CAGR of 6.3% during the forecast period of 2020-2025.

The market for TMT bars in India is also driven by the government’s focus on infrastructure development, as well as the increasing construction of affordable housing. The government has announced several initiatives to boost the construction industry, including the Pradhan Mantri Awas Yojana (PMAY) and the Smart Cities Mission.

Read Similar Articles: Know More about How to Start Mini Steel Plant (Billets and TMT Bar) Manufacturing Business | Setup Own Production Business of Mini Steel Plant (Billets and TMT Bar)

In addition, the growing real estate sector, increasing urbanization, and rising disposable incomes of people in India are also expected to drive the demand for TMT bars.

Benefits of Manufacturing TMT Bar:

Manufacturing TMT bars have several benefits, including:

- The Thermo-Mechanical Treatment (TMT) process improves the strength and ductility of the steel, making it more resistant to bending and breaking. This makes TMT bars ideal for use in the construction of buildings, bridges, and other structures, where strength and durability are important.

- TMT bars are made from high-grade steel and are highly resistant to corrosion. This makes them suitable for use in coastal areas or areas with high humidity, where traditional steel bars may rust and deteriorate quickly.

Related Feasibility Study Reports: Tmt Bars – Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue, Plant Economics

- TMT bars are a cost-effective solution for the construction industry. The TMT process improves the strength and ductility of the steel, which means that less steel is needed to achieve the same level of strength and durability. This reduces the overall cost of the construction project.

- TMT bars are an environment-friendly solution as they are produced through a closed-loop process which reduces the emissions of CO2 and other pollutants.

- TMT bars are easy to handle and transport as they are available in different sizes and are easy to cut and bend.

- The TMT process imparts a distinctive pattern, known as the Fe-O-Fe (ferrite-pearlite-ferrite) pattern, on the surface of the bars. This pattern is an indication of the quality of the TMT bars and is used as a benchmark for quality control.

- TMT bars are available in different grades, such as Fe 415, Fe 500, Fe 550, and Fe 600, depending on the strength and ductility required for a particular application, which makes it more customizable to suit the needs of the construction project.

Read our Books Here: The Complete Book on Construction Materials

Raw Materials Requirement:

The raw materials required for the TMT bar manufacturing business are:

Steel billets: The main raw material for TMT bars is steel billets. These are small, square-shaped pieces of steel that are used as the starting material for TMT bars. Steel billets are typically made from a mixture of iron and carbon, and are available in different grades based on their chemical composition.

Scrap steel: Some TMT bar manufacturers also use scrap steel as a raw material. This is steel that has been recovered from other sources, such as old buildings or vehicles, and is melted down and reused to make new TMT bars.

Fuel: TMT bars are made by heating the steel billets to high temperatures, which requires a large amount of fuel. This fuel can be in the form, of coal, natural gas, or any other suitable fuel.

Chemicals: Some TMT bar manufacturers may also use chemicals such as fluxes, which are added to the steel to improve its properties during the manufacturing process.

Power: TMT bar manufacturing requires a significant amount of power to operate the equipment and heat the steel billets.

Registration, Certificates, and Licence Required:

Starting a TMT bar manufacturing business requires obtaining several registrations, certificates, and licenses, including:

- Business Registration

- Factory Registration

- Environmental Clearance

- Trade License

- Fire License

- BIS Certification

- VAT Registration

- GST Registration

Land Acquisition:

Land acquisition is an important step in setting up a TMT bar manufacturing business. The land requirement for a TMT bar manufacturing unit depends on the scale of the project and the production capacity. A TMT bar manufacturing unit typically requires a large area of land for the installation of various equipment and machinery, as well as for storage and other facilities. The ideal location for a TMT bar manufacturing unit would be an industrial area, with easy access to transportation and power supply.

When acquiring land, it is important to ensure that the land is zoned for industrial use and meets all local zoning and land-use regulations. It is also important to ensure that the land is adequately sized to accommodate the manufacturing unit, storage facilities, and any other required infrastructure. Additionally, the land should have easy access to transportation for the movement of raw materials and finished products.

In some cases, the land may need to be purchased, while in other cases, it may be leased from a landlord or the government. Before finalizing the land acquisition, it is important to conduct due diligence to ensure that the land is suitable for the TMT bar manufacturing unit.

Investment:

Starting a TMT bar manufacturing business can be a significant investment. The total investment required will depend on the scale of the project and the production capacity. The major cost components include the cost of land and building, the cost of machinery and equipment, the cost of raw materials, working capital, and marketing expenses.

A small-scale TMT bar manufacturing unit can be set up with an investment of around INR 20-30 million (approximately $280,000 – $420,000) which includes land and building, machinery and equipment, and other miscellaneous expenses. However, if the unit is planned on a larger scale, the investment can go up to INR 100 million (approximately $1,4 million) or more depending on the production capacity and technology used.

Conclusion:

The manufacturing businesses of TMT Bar are gaining in popularity these days. With a variety of advantages that they offer, such as fast production times, high-quality products, and low costs, these businesses are bound to be a big success. If you’re interested in starting your own manufacturing business, be sure to read this blog post for more information on the subject. By following these tips, you can start building a successful manufacturing business for TMT Bar today!

Visit the page Select and Choose the Right Business Startup for You for sorting out the questions arising in your mind before starting any business and know which start-up you can plan.

We, at NPCS, endeavor to make business selection a simple and convenient step for any entrepreneur/startup. Our expert team, by capitalizing on its dexterity and decade’s long experience in the field, has created a list of profitable ventures for entrepreneurs who wish to diversify or venture. The list so mentioned is updated regularly to give you a regular dose of new emerging opportunities.

Click here to send your queries/Contact Us

Reasons for Buying NIIR Report:

- Our research report helps you get a detailed picture of the industry by providing an overview of the industry along with the market structure and classification.

- Our report provides market analysis covering major growth driving factors for the industry, the latest market trends and the regulatory framework of the industry.

- Our Report provides an analysis and in-depth financial comparison of major Players / Competitors.

- Our Report provides indispensable buyers' data with their company financials as well as the contact details, which can be an important tool in identifying the target customers.

- Our report provides forecasts of key parameters which help to anticipate the industry performance.

- We use reliable sources of information and databases. And information from such sources is processed by us and included in the report.

NPCS has access to and has studied the TMT Bar market. All TMT Bar producers, researchers, technocrats, consultants, and new business owners can benefit from the research.

See More Links:

- Start a Business in Asia

- Start a Business in Potential Countries for Doing Business

- Best Industry for Doing Business

- Business Ideas with Low, Medium & High Investment

- Looking for Most Demandable Business Ideas for Startups

- Startup Consulting Services

- Start a Business in Africa

- Start a Business in India

- Start a Business in Middle East

- Related Videos

- Related Books

- Related Projects

- Related Market Research Reports

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐮𝐬

NIIR PROJECT CONSULTANCY SERVICES, DELHI

An ISO 9001:2015 Company

ENTREPRENEUR INDIA

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: npcs.ei@gmail.com

Tel: +91-11-23843955, 23845654, 23845886

Mobile: +91-9097075054, 8800733955

Website: https://www.entrepreneurindia.co

DPP_20Art23