E-waste is a growing problem that threatens our environment and our health. Electronic devices contain a wide range of materials, including hazardous substances that can pose a risk to our planet and its inhabitants. But, fortunately, there is a solution to this problem: e-waste recycling plants. These plants can recycle electronic devices and recover valuable materials, reducing the environmental impact of e-waste and preventing it from ending up in landfills.

E-waste recycling plants are facilities that specialize in the recycling of electronic waste. They have the expertise, equipment, and technology needed to break down and process electronic devices, separating valuable materials from hazardous ones. The materials that can be recovered from e-waste include precious metals such as gold, silver, and copper, as well as other materials like plastics, glass, and rare earth metals. These materials can be reused to create new products, reducing the need for mining and conserving valuable resource.

Visit this Page for More Information: Start a Business in E-Waste Recycling Industry

Future of E-Waste Recycling Plants

The future of e-waste recycling plants is bright, and the industry is already experiencing rapid growth. As technology advances and more electronic devices are produced, the amount of e-waste generated is only going to increase. This means that there will be an increasing demand for e-waste recycling plants and that these facilities will have to become more efficient and innovative to keep up with the demand.

Related Business Plan: E-Waste Recycling Plant

These recycling plants can make a difference in the recovery of rare earth metals. These materials are crucial for producing many electronic devices, but they are also in limited supply. By developing new techniques for recovering rare earth metals, e-waste recycling plants can help reduce the environmental impact of mining and preserve these valuable resources for future generations. Finally, e-waste recycling plants will need to focus on sustainability in the future.

To tackle the concern of growing e-waste, E-Waste Recycling Plant manufacturing plants have emerged as a revolutionary solution. These plants are dedicated to the recycling and reusing of electronic waste, thus helping to reduce the amount of e-waste that ends up in landfills.

Read Similar Articles: WASTE MANAGEMENT AND RECYCLING

Production Process

these plants go through a number of steps in the production process, including:

Collection of E-waste: The first step involves collecting electronic waste from various sources, including households, businesses, and industries. The waste is then transported to the recycling plant, where it undergoes sorting.

Sorting of E-waste: The next step involves sorting the e-waste according to its type, such as computer parts, batteries, wires, and cables. This step is crucial as it helps to separate the materials that can be recycled from those that cannot.

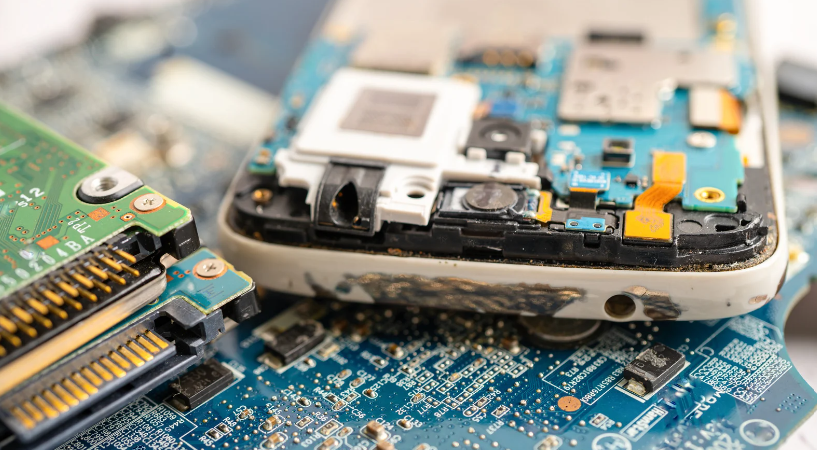

Dismantling of E-waste: After sorting, the e-waste is dismantled to separate the reusable components from the non-reusable ones. This process involves removing the parts that are in good condition, such as memory chips, circuit boards, and processors.

Related Feasibility Study Reports: E-waste Recycling Plant

Recycling: The reusable components are then sent for recycling, where they are processed and made into new products. This step reduces the need for mining new resources, thus conserving natural resources and reducing the carbon footprint.

Proper Disposal of Non-reusable Components: The non-reusable components that cannot be recycled are sent for proper disposal, ensuring that they do not pose any harm to the environment.

The production process of E-Waste Recycling Plant manufacturing plants is not only environmentally friendly, but it also generates employment opportunities, thus contributing to the economy. These plants help to reduce the amount of e-waste that ends up in landfills, thus conserving natural resources, reducing greenhouse gas emissions, and mitigating the impact of e-waste on human health.

A Booming Market for the Next 20 Years. The need for proper e-waste management has given rise to the e-waste recycling plant manufacturing market. This market is expected to grow at an unprecedented rate over the next 20 years, and major companies and names are getting involved.

According to a report by Grand View Research, the global e-waste recycling plant manufacturing market is expected to reach $40.26 billion by 2025, growing at a compound annual growth rate (CAGR) of 15.3% from 2020 to 2025. The report attributes the growth to the increasing demand for e-waste recycling plants and the rising awareness of environmental concerns among consumers.

Read our Books Here: The Complete Technology Book on E-Waste Recycling (Printed Circuit Board, LCD, Cell Phone, Battery, Computers) 3rd Revised Edition

The Asia Pacific region is expected to dominate the market, with China being the largest market for e-waste recycling plants. This is due to the high volume of e-waste generated in the country and the stringent regulations that the Chinese government has put in place for e-waste management. The North American and European regions are also expected to witness significant growth, as they are home to some of the biggest electronic manufacturing companies in the world.

The following top manufacturers are active in the market for e-waste recycling plants:

- Sims Metal Management Ltd.

- Electronic Recyclers International Inc.

- Stena Metall AB

- Umicore SA

- Aurubis AG

- TES-AMM Pte Ltd.

- MRI e-cycle solutions

- CRT Recycling Inc.

- Global Electric Electronic Processing Inc.

- Lifespan Technology Recycling Inc.

These companies are investing heavily in research and development to develop efficient and sustainable e-waste recycling plants. The market players are focusing on innovative technologies to increase the efficiency of the recycling process, reduce the environmental impact, and improve the quality of the recycled material.

It’s time to embrace the future of e-waste recycling and work together to create a more sustainable and responsible world.

Click here to send your queries/Contact Us

Niir Project Consultancy Services (NPCS) is a trusted global consultancy that delivers excellence in a diverse range of services. Our portfolio includes investment opportunities, technology transfers, pre-feasibility studies, business plans, project identification, and feasibility analysis. We specialize in identifying profitable industrial projects, conducting thorough project analysis, planning resources, and providing detailed capital and operational cost projections. Our economic feasibility studies offer valuable insights into market potential, funding options, and plant and equipment selection.

As a leading player in the industry, NPCS boasts a wealth of technical knowledge and intellectual assets. We are a reliable source of professional information for entrepreneurs in India and beyond, with a team of experienced market researchers and industry experts. Our advanced industrial, business, and commercial databases provide a global platform for the entire entrepreneurial ecosystem, offering the right projects for investment, and comprehensive market surveys and research.

Reasons for Buying NIIR Report:

- Our research report helps you get a detailed picture of the industry by providing an overview of the industry along with the market structure and classification.

- Our report provides market analysis covering major growth driving factors for the industry, the latest market trends and the regulatory framework of the industry.

- Our Report provides an analysis and in-depth financial comparison of major Players / Competitors.

- Our Report provides indispensable buyers' data with their company financials as well as the contact details, which can be an important tool in identifying the target customers.

- Our report provides forecasts of key parameters which help to anticipate the industry performance.

- We use reliable sources of information and databases. And information from such sources is processed by us and included in the report.

See More Links:

- Start a Business in Asia

- Start a Business in Potential Countries for Doing Business

- Best Industry for Doing Business

- Business Ideas with Low, Medium & High Investment

- Looking for Most Demandable Business Ideas for Startups

- Startup Consulting Services

- Start a Business in Africa

- Start a Business in India

- Start a Business in Middle East

- Related Videos

- Related Books

- Related Projects

- Related Market Research Reports

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐮𝐬

NIIR PROJECT CONSULTANCY SERVICES, DELHI

An ISO 9001:2015 Company

ENTREPRENEUR INDIA

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: npcs.ei@gmail.com

Tel: +91-11-23843955, 23845654, 23845886

Mobile: +91-9097075054, 8800733955

Website: https://www.entrepreneurindia.co

SS_20Art23