Nickel is an incredibly valuable metal and its uses span across a variety of industries. But extracting and processing nickel metal from nickel ore can be an incredibly complex process. If you’re looking to unlock the potential of your nickel processing business, this guide is here to help. From the basics of understanding nickel ore to the best practices for extracting and processing nickel metal, this guide will provide you with the knowledge and insight you need to confidently move forward with your nickel processing business. So, let’s get started!

Visit this Page for More Information: Start a Business in Mining Industry

Introduction to Nickel Ore Processing

Nickel ore is a mineral composed primarily of nickel and iron. The ore is processed in a number of steps to extract the nickel and iron, which are then sold as products. The first step in processing is to crush the ore and separate the nickel-bearing minerals from the other minerals. This is done by flotation, in which the nickel-bearing minerals are separated from the other minerals by being selectively floated to the top of the flotation cell. The next step is to leach the nickel and iron from the ore using sulfuric acid. This is followed by a process of solvent extraction, in which the nickel and iron are separated from the acid using a solvent. The final step is to electrowin the nickel and iron, which involves passing an electric current through the solution to deposit the metals on the cathode.

Processing Techniques for Nickel Ore

When processing nickel ore, you’ll need to decide what kind of processing technique will be best suited for the ore. Each ore will have its own unique characteristics, so it’s important to ensure that the correct processing technique is selected. For example, an ore with a low iron content is best suited for an iron removal technique. With that in mind, there are three processing techniques that are commonly used: gravity separation, flotation, and magnetic separation.

Gravity Separation – This technique is used for ores with a specific gravity that is higher than that of water.

Flotation – Flotation is used for ores with a high sulfide content and a low iron content. Magnetic

Separation – This technique is used for ores that contain high amounts of iron, such as pentlandite.

Related Business Plan: Mining, Quarrying, Mineral and Ore Processing, Coal, Iron Ore, Limestone, Chromite and Granite Mining

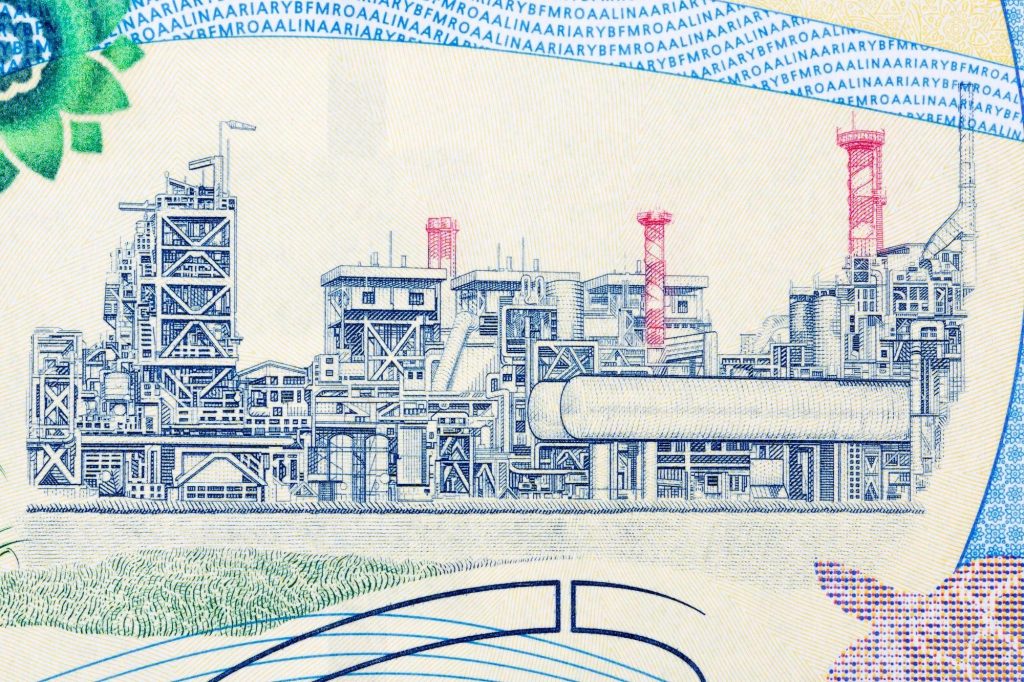

Nickel Ore Processing Equipment

Depending on the type of extraction method that you use and the chemical composition of your ore, you may need to use specific equipment for nickel ore processing. For example, for ores that contain a high level of nickel, you’ll need a magnetic separator to remove the nickel. There are also a number of different types of flotation equipment that you can use, depending on the chemical composition of your ore. Flotation equipment can be broken down into two categories: air lift flotation and mechanical flotation. Air lift flotation is used to process fine materials with a low specific gravity while mechanical flotation is used for coarse materials with a high specific gravity. Once the equipment has been selected, you’ll need to ensure that it is properly maintained. Poorly maintained equipment can lead to reduced processing efficiency and even damage to your equipment.

Nickel Ore Processing Plant Design Considerations

As with any type of commercial manufacturing process, it’s important to design your plant appropriately. This will ensure that your equipment is properly sized and that there is enough room for efficient operation. It will also help to keep your operation safe and your costs down. There are several factors that you’ll need to take into account when designing your plant: – Size of the plant – The size of your plant will depend on the amount of ore that you’ll be processing at once. You’ll need to estimate the amount of ore that you’ll be mining each year and multiply it by the average amount of nickel that is found in the ore. This will give you an idea of how much ore you’ll need to process and will help you determine the size of your plant. – Technical parameters of equipment – The type and amount of equipment that you’ll need in your nickel ore processing plant will depend on the type of ore that you mine and the extraction method that you use.

Read Similar Articles: The Metals and Mining Industry in India: Growing Industries of the Future

Safety Tips When Handling Nickel Ore

Processing nickel ore can be a dangerous task, especially when working with flotation equipment. As such, it’s important to follow safety precautions to prevent accidents and injuries. When selecting your flotation equipment, it’s important to remember that fine materials will flow into the flotation cell while coarse materials will not. This means that there is a risk of explosion when working with coarse materials. To prevent this, you’ll need to provide adequate ventilation and install appropriate filters to reduce the risk of an explosion. You should also take precautions to protect yourself from potential damage when handling equipment. This can include wearing protective clothing such as gloves, long-sleeve shirts, and long pants.

Cost-Saving Strategies for Nickel Ore Processing

As with any process, there are ways to reduce costs while keeping your operation running smoothly. When it comes to nickel ore processing, there are a few things that you can do to help reduce costs. First, you should be sure to select the right extraction method for your ore. This will help you to reduce the amount of processing required. You should also be mindful of your equipment selection and make sure that you choose equipment that is compatible with the ore. Another way to reduce costs is by controlling your operating costs. You can do this by selecting the appropriate equipment for your operation and running your equipment at maximum efficiency.

Related Feasibility Study Reports: Beneficiation Of Chromium, Nickel And Manganese Ore – Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Cost Of Project

Challenges of Nickel Ore Processing

There are many challenges that can be encountered during nickel ore processing. However, these challenges can be overcome with careful planning. For example, the equipment used in the extraction process must be properly sized and selected to ensure that it can effectively process the ore. If the equipment is too small, it will take longer to process the ore and will increase the amount of energy required to run the equipment. If the equipment is too large, it will be more difficult to operate and will require more maintenance and repair. Additionally, you’ll need to ensure that you have sufficient space in your plant to accommodate the equipment.

Read our Books Here: The Complete Book on Ferroalloys (Ferro Manganese, Ferro Molybdenum, Ferro Niobium, Ferro Boron, Ferro Titanium, Ferro Tungsten, Ferro Silicon, Ferro Nickel, Ferro Chrome)

Conclusion

There’s no denying that nickel is a valuable metal that can be used in a variety of industries. But extracting and processing nickel metal from nickel ore is a complex process that can be difficult for some businesses. This guide was created to help businesses that are interested in processing nickel ore and extracting nickel metal from it. This guide begins by explaining the basics of nickel ore and what makes it unique from other types of ore. It then goes on to explain the various extraction methods and processing techniques that can be used for different types of nickel ore. This guide also provides tips for cost-saving strategies, best practices for safety, and design considerations for a processing plant. In the end, this guide will help you unlock the potential of your nickel processing business and allow you to confidently process nickel ore.

Visit the page Select and Choose the Right Business Startup for You for sorting out the questions arising in your mind before starting any business and know which start-up you can plan.

We, at NPCS, endeavor to make business selection a simple and convenient step for any entrepreneur/startup. Our expert team, by capitalizing on its dexterity and decade’s long experience in the field, has created a list of profitable ventures for entrepreneurs who wish to diversify or venture. The list so mentioned is updated regularly to give you a regular dose of new emerging opportunities.

Click here to send your queries/Contact Us

NPCS

The Nickel Metal from Nickel Ore project report by NPCS is a comprehensive document that provides an in-depth analysis of the extraction and processing of nickel metal from nickel ore. The report covers all aspects of the project, from the initial feasibility study to the final commissioning of the plant. It includes a detailed description of the process, as well as a comprehensive list of the equipment and materials required for the project. The report also provides a detailed financial analysis, including a cost-benefit analysis and a sensitivity analysis.

Reasons for Buying NIIR Report:

- Our research report helps you get a detailed picture of the industry by providing an overview of the industry along with the market structure and classification.

- Our report provides market analysis covering major growth driving factors for the industry, the latest market trends and the regulatory framework of the industry.

- Our Report provides an analysis and in-depth financial comparison of major Players / Competitors.

- Our Report provides indispensable buyers' data with their company financials as well as the contact details, which can be an important tool in identifying the target customers.

- Our report provides forecasts of key parameters which help to anticipate the industry performance.

- We use reliable sources of information and databases. And information from such sources is processed by us and included in the report.

See More Links:

- Start a Business in Asia

- Start a Business in Potential Countries for Doing Business

- Best Industry for Doing Business

- Business Ideas with Low, Medium & High Investment

- Looking for Most Demandable Business Ideas for Startups

- Startup Consulting Services

- Start a Business in Africa

- Start a Business in India

- Start a Business in Middle East

- Related Videos

- Related Books

- Related Projects

- Related Market Research Reports

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐮𝐬

NIIR PROJECT CONSULTANCY SERVICES, DELHI

An ISO 9001:2015 Company

ENTREPRENEUR INDIA

106-E, Kamla Nagar, Opp. Mall ST,

New Delhi-110007, India.

Email: npcs.ei@gmail.com

Tel: +91-11-23843955, 23845654, 23845886

Mobile: +91-9097075054, 8800733955

Website: https://www.entrepreneurindia.co

NS_20Art22